CALSA (Compañía Argentina de Levaduras S.A.), a key subsidiary of the global AB Mauri group, is a leading producer of yeast and baking ingredients with a strong industrial footprint in Argentina and across Latin America. With over 100 years of expertise in fermentation technologies, CALSA serves both artisanal and large-scale bakeries. Operating major plants in Lanús and Tucumán, the company is committed to innovation and operational excellence, actively exploring Industrial IoT connectivity to modernize its processes. As part of its digital transformation, CALSA recognized Industrial IoT connectivity as a strategic lever to unify operations, enhance visibility, and stay competitive in a fast-evolving manufacturing landscape.

The Challenge of Achieving Industrial IoT Connectivity

CALSA, a key subsidiary of AB Mauri and one of the world’s leading yeast manufacturers, operates two major production plants in Argentina, Lanús and Tucumán. While each facility maintained high standards of quality and performance, they functioned independently, with data captured and stored locally in disparate systems. This created an operational bottleneck where leadership lacked unified, real-time visibility over production metrics, energy usage, and logistics performance across locations.

Critical data, ranging from machine output and line efficiency to fleet movement and power consumption, was either manually consolidated or not compared at all, leading to slow reaction times and missed opportunities for optimization. Without a centralized infrastructure, strategic decisions were based on incomplete or outdated information, complicating efforts to coordinate production, reduce energy waste, and streamline logistics. CALSA needed a scalable, non-intrusive digital solution that could connect legacy equipment, unify operational data, and enable dynamic, real-time oversight across plants.

The Solution

Implementation Benefits

The deployment of the solution enabled CALSA to unlock several strategic advantages:

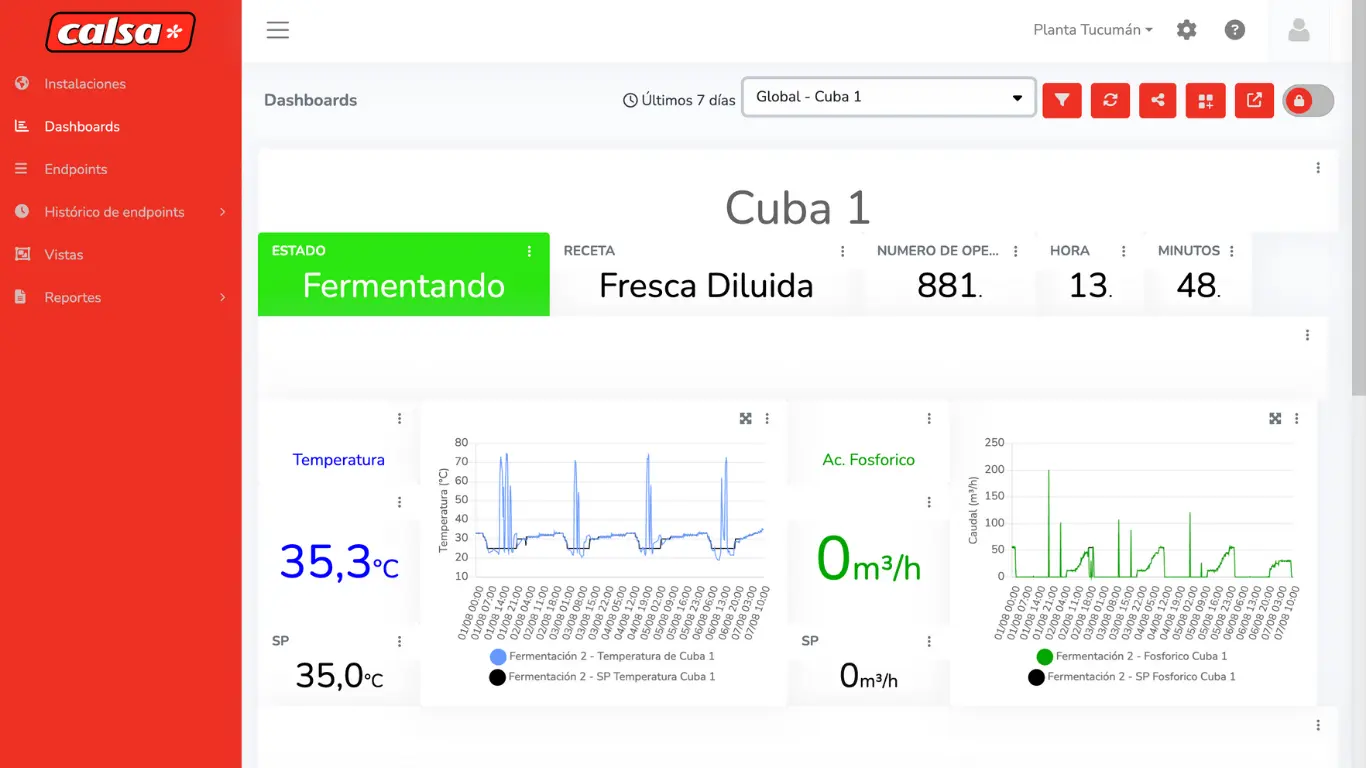

- Operational Unification: All plants now communicate through a centralized data infrastructure.

- Energy Optimization: Consumption tracking at machine-level allows identification of inefficiencies and prevents penalties on electric bills.

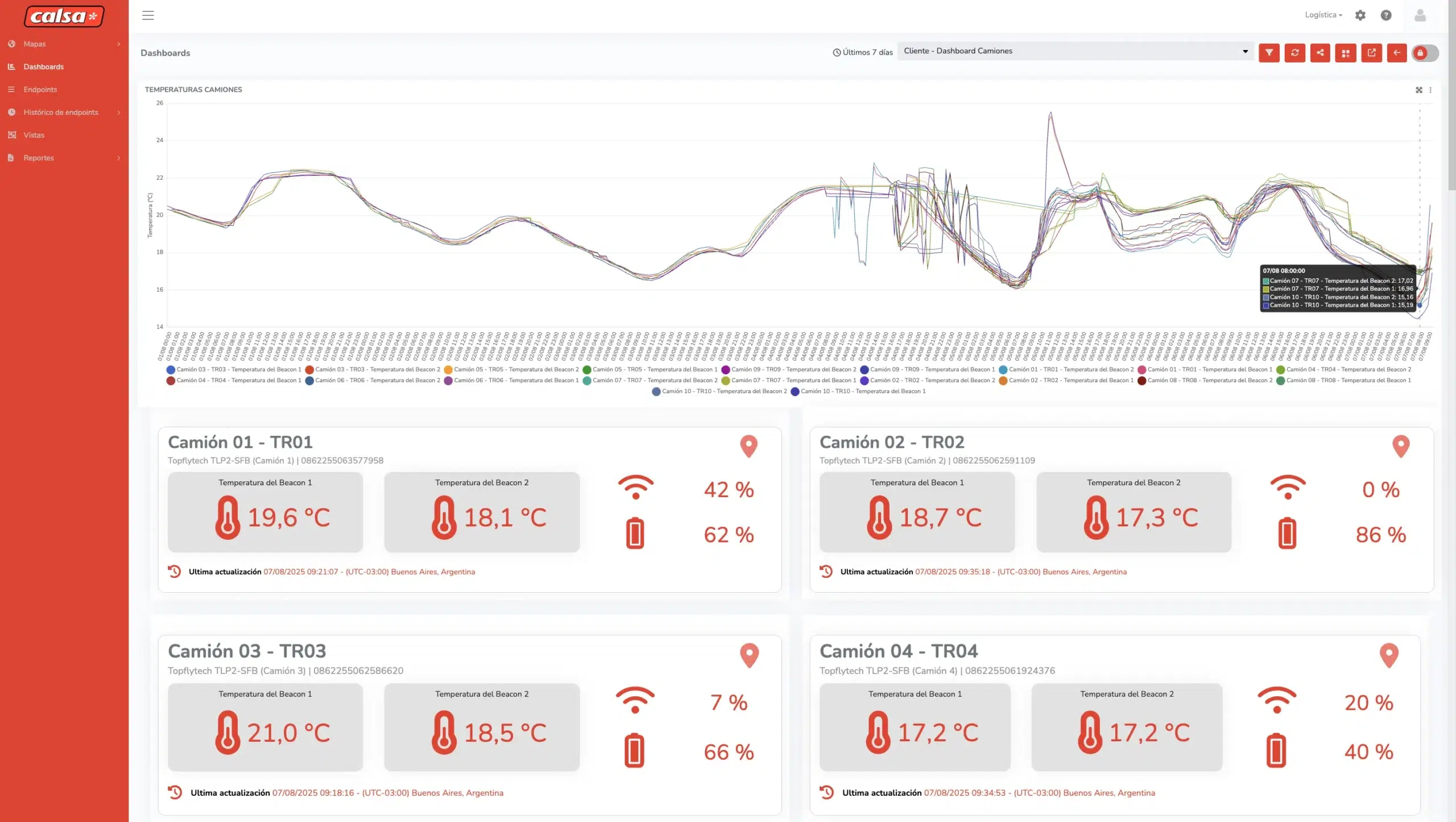

- Logistics Coordination: Real-time GPS data has improved fleet visibility and inter-plant coordination.

- Custom Visual Interfaces: From operators to executives, each role receives relevant KPIs through dedicated dashboards.

- Infrastructure Security: Including server rooms in monitoring workflows strengthens the resilience of critical systems.

Impact of Industrial IoT Connectivity on CALSA’s Operations

Conclusion

CALSA’s journey toward digital transformation is a clear demonstration of what’s possible when industrial expertise meets scalable, intelligent technology. By leveraging Cloud Studio’s IoT Platform, CALSA unified its operations across geographically dispersed plants, gained real-time control over critical processes, optimized energy usage, and significantly improved logistics coordination, all without disrupting existing infrastructure.

More than just a technological upgrade, this implementation laid the foundation for a culture of continuous improvement, data-driven decision-making, and strategic scalability. The platform didn’t just solve a problem, it became a long-term enabler of innovation and efficiency.

But CALSA’s success is not an isolated case. It reflects a broader opportunity across the manufacturing and process industries. Many organizations face similar challenges: siloed data, inefficient energy use, lack of operational visibility, and disconnected legacy systems. CALSA’s results prove that these obstacles can be overcome, not with massive capital investment, but with smart, modular solutions that adapt to each plant’s reality.

For companies in the food and beverage sector and beyond, this case sets a precedent: Industrial IoT is not just a buzzword, it’s a tangible, accessible path to achieving Industry 4.0 at scale.